Some information may be outdated.

A watchdog group for pipeline safety sent video and allegations to local and state officials last week that have raised concerns that Fidelity Exploration and Production’s natural gas pipeline construction near Dead Horse Point presents possible safety hazards.

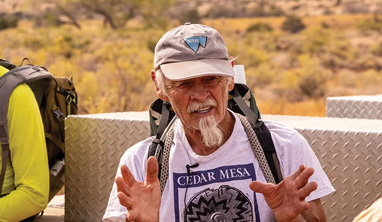

“I have spent the last four days observing, filming and documenting activities of construction on the Dead Horse Lateral Pipeline project,” Western Ranchers Alliance (WRA) president Dennis Stiles said. “There have been numerous violations during construction with regard to the specs set forth in the environmental assessment (EA).”

The WRA is a non-profit organization based in Durango, Colo., that advocates for pipeline safety and has a member base that covers eight western states and includes farmers, ranchers, community-interest groups, and gas companies, among others, according to its Web site.

Responding to the allegations, Tim Rasmussen, spokesperson for Fidelity and its sister company WBI Energy said, “We are building a pipeline that we are purposely over-designing for the conditions to ensure public safety and safe operation of the line.”

The pipeline that Fidelity is constructing will transport natural gas captured from its Kane Creek Unit oil wells near Dead Horse Point State Park to a processing facility near Blue Hills Road, north of Moab, according to the Bureau of Land Management public comments bulletin and its Environmental Assessment. The 24-mile-long pipeline would roughly parallel state Route 313 and the Dubinky Well Road. Four miles of the pipeline would be buried.

“We are very concerned with the safety aspect of this project because of the 18 miles above ground section in a tourist recreation area,” Stiles said. “We feel there is a huge risk to the public if a rupture occurred. Therefore, these guidelines in the EA that the gas company agreed to uphold, should be strictly enforced.”

The BLM environmental assessment states “While this ‘gathering line’ will not be regulated, the pipeline would be designed and constructed to meet and exceed federal and industry standards that would be applied to a similar transmission pipeline.”

Transmission pipelines, which transport gas from a gathering line or storage facility to a distribution center, are held to construction regulations set by the American Petroleum Institute (API) in the code book known as API 1104, Standards for Welding Pipelines and Related Facilities.

Gathering lines—lines that transport gases from their source to a processing facility—however, are far less regulated, regardless of their length.

According to Damon Hill, public affairs specialist with the Pipeline and Hazardous Materials Safety Administration (PHMSA), the Dead Horse pipeline is a Class I rural gathering pipeline, which is not regulated by PHMSA or “any other governing body and so it isn’t legally bound to transmission line specifications. “

The pipeline is being constructed through land managed by the BLM. BLM Moab Field Office field manager Beth Ransel said that the Department of Transportation would have authority over a transmission pipeline, but that since “the Dead Horse pipeline is considered an intrastate (gathering) pipeline, this work is performed by the Gas Pipeline Safety Group of the Utah Division of Public Utilities within the Utah Department of Commerce,” Ransel said.

However, Utah Division of Public Utilities spokesperson told the Moab Sun News that they are not presently exercising authority over the pipeline.

“The Division is currently evaluating this line to determine whether it has jurisdiction over the line. If jurisdiction is found, the Division will exercise that jurisdiction. Because the line is a gathering line, the inspection and regulation regime under federal and state law is a bit different than for typical distribution and transmission lines,” spokesperson for Utah’s Division of Public Utilities Jennifer Bolton said.

Fidelity’s Rasmussen said that there is no state or federal agency regulating the pipeline’s construction, but that they are meeting all “NEPA (National Environmental Policy Act) process and the Environmental Assessment stipulations that we must comply with.”

Rasmussen said that inspection of the construction is being handled by a private subcontractor, Big Horn Technical, under the management WBI Energy, Inc.

Damon Hill, public affairs specialist with the Department of Transportation’s PHMSA, said that the lack of regulation of gathering pipelines is something that the agency is reviewing.

PHMSA is currently in the process of what it calls “rule-making” to bring “a good majority if not all of the unregulated natural gas gathering lines under regulations,” Hill said. “The problem is that rule- making is still in the works.”

Stiles and his friend, Chad Gilbert, a member of Pipeliners Local Union No. 798, spent days observing and filming the construction of the pipeline.

“The EA said it would be treated the same or above the standards of a transmission line,” Stiles said. “That’s not what they’re doing.”

He said his concerns are primarily that the pipe is above ground and the welding procedures aren’t meeting PHMSA standards.

“According to PHMSA, any line that follows the rules of a transmission line, it is mandatory for a minimum amount of 18 feet of cover,” Stiles said. “That pipe needs to be buried.”

Burying the pipe, Stiles said, mitigates expansion and contraction movement of the pipe, that can cause abrasion and wear the material over time. As well, it prevents the possibility of collision with the pipe, such as from a recreational vehicle or stray hunting bullet.

Stiles and the Fidelity spokesperson both cite the same section of American Petroleum Institute (API) code to either condemn or support the welding procedures that Stiles has videotaped.

“There wasn’t a single weld I witnessed that they waited until the welder had run the whole bead before releasing the clamp,” Stiles said, speaking of the internal clamps that are used to align and hold pipe ends together for the weld. “And setting it down with a tractor. What that means is they let the pipe down on the skids. Now it’s really in a bind; not only are the clamps released but the whole weight of the pipe, which was held by the sling or cable, is allowed to be like a wet noodle bouncing on the ground when the weld isn’t even complete.”

The API codebook, section 7.3 states “when an internal lineup clamp is used and conditions make it difficult to prevent movement of the pipe or if the weld will be unduly stressed, the root bead shall be completed before clamp tension is released.”

Rasmussen, speaking for Fidelity, said “the regulation specifies that the removal of internal line-up clamps before the root bead is completed is permissible,” as long as other specifications are met.

The actual API Code, section 7.3 states “When it is permissible to remove the lineup clamp before the root bead is completed…” certain specifications should be met.

“The code gives the owner the latitude to let the contractor release the clamp a little bit before a hundred percent” said John Wormeli, founder of the National Welding Inspection School. “If it will be unduly stressed then you should consider holding the clamp 100 percent. But if you’re going across flat land and not going up and down mountains, then it’s not unusual for the owner of the company to allow the release of the clamp after 75 percent of the root bead is completed.”

Rasmussen did not speak to the issue of stress on the pipe, but said that the manufacturer of the clamps said they were “being used as designed, and that they must be released prior to a 100-percent circumferential weld. This is necessary to move the alignment ‘thumb’ out of the way so the clamp is not unintentionally welded to the pipe.”

Wormeli disagreed with this reasoning, saying that, what he called the “shoes” that align the pipes one end to the other, “are 2 and 3 inches away from each side of the weld so if you want to hold the clamp 100 percent, there is no danger whatsoever of welding the clamp to the pipe.”

The BLM said it is looking into the concerns that have been raised.

“The BLM is actively monitoring the construction of the Dead Horse Lateral Pipeline,” Ransel said. “The BLM takes pipeline safety concerns very seriously. Upon notification earlier in the week of the concern regarding welding procedures, the BLM initiated a review of the information submitted and has been actively coordinating with both Fidelity and the construction compliance monitor on this matter.”

Rasmussen points to the fact that the pipeline is not bound by PHMSA regulations and they “are meeting or exceeding Department of Transportation standards related to the construction of this line.”

At least two gas pipelines have exploded in Moab’s past. In 1956, a natural gas pipeline explosion forced uranium mines to shut down, according to the Spokane Daily Chronicle from April 2 of that year. The blast occurred while the pipeline was being put under pressure to check for weaknesses.

More recently, in 1998, a natural gas liquids pipeline ignited near U.S. Highway 191, injuring four pipeline workers and melting the asphalt in the road. An OSHA report for the incident states that a bulldozer struck a 10-inch-diameter gas line, resulting in a high pressure leak that was then ignited by a semi-truck running nearby, causing the pipeline to explode.

Watchdog group says construction falls short of industry best practices; builder says it is meeting or exceeding standards

“We are very concerned with the safety aspect of this project because of the 18 miles above ground section in a tourist recreation area. We feel there is a huge risk to the public if a rupture occurred. Therefore, these guidelines in the EA that the gas company agreed to uphold should be strictly enforced.”

Appreciate the coverage? Help keep local news alive.

Chip in to support the Moab Sun News.