Some information may be outdated.

The U.S. Department of Energy has completed about one-third of a project to move 16 million tons of uranium tailings from the banks of the Colorado River, near Moab, to a permanent disposal site 30 miles north, near Crescent Junction.

It’s long, slow work, but it’s getting done.

The project, called the Moab Uranium Mill Tailings Remedial Action (UMTRA) Project, began in April 2009.

At the end of May, workers had removed not quite a third of the tailings, which is the waste product left from the uranium mill that operated there from 1956 to 1984.

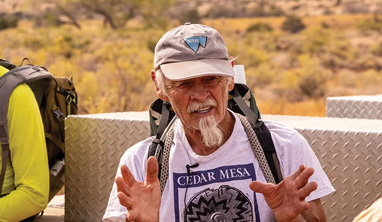

Work had increased for 18 months because of federal stimulus money, said Lee Shenton, the UMTRA liaison. During that time period, crews were moving 180,000 to 200,000 tons of tailings a month, he said.

Now, the current contract allows workers to move about 55,000 tons a month.

Portage Inc. of Idaho has a five-year contract to manage the project. Because of the funding restraints, Portage officials have decided to work nine months out of the year moving tailings. They’ll rest December through February and will also take off the entire week of a holiday (July 2-6, for example).

Portage has a total of 117 employees working on the project, Shenton said. Of those, about 80 will be tasked with finding other work during the holiday weeks and three months off.

But, Shenton said, it’s not Portage’s fault they were asked to move only 650,000 tons of tailings a year.

“It’s more cost effective for them to operate only nine months of the year,” Shenton said.

The federal bill that initially funded the Moab UMTRA project specified an end date of 2019. At this rate, Shenton said, work will take until 2028.

The project team estimates a completion year of 2025.

Either way, it’s a long time from now.

So, until then, the crews will keep working like clockwork.

The Moab Tailings Project Site is located approximately 3 miles northwest of Moab. It includes the former Atlas Minerals Corporation uranium-ore processing facility. The site is situated on the west bank of the Colorado River at the confluence with Moab Wash. The site encompasses 480 acres, of which approximately 130 acres is covered by a uranium mill tailings pile.

Tailings are what’s left behind after a mill takes uranium out of the land. The sandy stuff has residual uranium and residual chemicals.

“There are very definite risks and hazards associated with tailings, but they’re nowhere near those associated with spent electrical rods,” Shenton said.

The amount of radiation the workers who spend 40 hours a week on the site are exposed to is the equivalent of 20 chest X-rays a year, he said.

The Department of Energy restricts access to the radiological control area of the site where the mill tailings and the highest concentrations of soil contamination exist. Security staff are on site 7 days per week, while maintenance activities, erosion control measures, tailings excavation and conditioning, ground water remediation activities, and health and safety oversight are conducted 4-5 days per week.

At the site, bulldozers peel the top layer off the tailings pile and push it down to the bottom. A backhoe then scoops up the dirt and puts it into a pile.

The tailings must dry before they can be placed in the containers.

The dried tailings then go into containers that look like train cars.

The open containers are then driven into what Shenton calls the “liddng structure” to be capped, so no dust blows away.

Finally, the truck and sealed container are rinsed, and the container is loaded onto a train.

The train has 132 cars, Shenton said, and each holds four containers. Each container holds about 35 tons of tailings.

The train takes the tailings to an “engineered disposal cell,” 31 miles north of the site, just to the east of Crescent Junction on I-70.

The tailings can be disposed there because of the area’s remote location and because the nature of the soils in that area make it safe to dispose low-level radiation.

The mancos shale in that soil is clay-like, Shenton said, so if it gets wet, it swells and self seals.

The cell is 40 feet deep and is stable with no cracks or leaks, he said. The layers prevent radon gas from escaping.

The Moab project ships one trainload of tailings to the cell each day.

Since the Colorado River runs behind the tailings site, officials are careful to monitor water quality and prevent contamination.

The tailings remediation site has 140 wells on it between the tailings pile and the river, Shenton said. They are there to intercept groundwater contamination from entering the river.

Shenton’s job isn’t without obstacles.

“The single biggest challenge I have is that the risks related to radiation aren’t understood by a good portion of the population,” he said. “Every risk for this project is well-known. It’s real. It’s measurable. But it’s also really low. I don’t want people to think they’re going to glow (if they use) the riverside trail.

For more information and updates, visit moabtailings.org.

Appreciate the coverage? Help keep local news alive.

Chip in to support the Moab Sun News.