Some information may be outdated.

About 100 people gathered for the opening of Moab’s new $12.4 million wastewater plant on Dec. 13, many of them smiling.

There were a lot of announcements for the accomplishment and awards to the staff at the Moab City Water Reclamation Facility, and everyone had at least one question for the many experts on-hand who helped to design the system. Several people recalled what they thought of, as one person said, “that awful, old facility that used to be over there” as they toured the new facility. This one, a cutting-edge example compared to its predecessor, is equipped with mechanisms like ultraviolet light rays in the final phase of filtration that give the water a much-needed cleanse, without the addition of chlorine.

Moab City Mayor Emily Niehaus hosted the ribbon-cutting ceremony, handing out balloons, flowers and plaques as Moab Chamber of Commerce Director Laici Shumway stood nearby with a very large pair of scissors to cut a white ribbon draped across the entrance.

Everyone chanted a countdown to the ribbon cutting — “3, 2, 1” — as Niehaus lifted the scissors and cut the bow. The signature celebration was followed by a round of applause. Observing the group’s applause, Moab City Manager David Everitt exclaimed, “Quite a turnout for a poop plant,” before pointing to the facility’s process flow schematic and hydraulic profile displayed on easels.

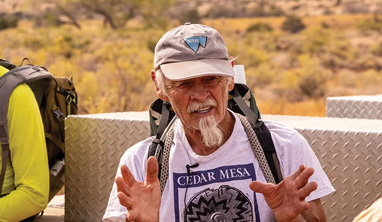

Greg Fosse, superintendent of the Moab Wastewater Reclamation Facility, thanked the community and the employees for being supportive of the new plant.

“It is already showing signs of exceeding expectations of what we expect of the plant,” Fosse told the crowd. “Rest assured, this plant will serve this community for decades to come… I just want to thank the City of Moab for giving me a chance to work with them.”

Fosse was joined at the ceremony by other officials and employees: Moab City Engineer Chuck Williams, wastewater facility employees Mark Luddington and Kent Ross, and Scott Baird, the deputy director for the Utah Department of Environmental Quality.

“This speaks to Moab, the community, everybody who has been involved in the process,” Baird said, explaining that the new plant aligns with the agency’s mission to “safeguard land, water and air through balanced use and regulation.”

The people in attendance who had reserved a tour in advance were separated into groups of about eight people.

Group 3 was led by Bob Mayers, the chief engineer for Bowen Collins, a firm contracted by the City of Moab in the creation of the new plant. As the tour began, one person in the group commented that he had read that same day’s New York Times feature about a sewage plant scuba diver in another country who had extracted a cow. Group 3 talked about what sorts of materials could be found at a wastewater facility — anything that could be flushed down the toilet or put into the sewer, Mayers said — and listed dentures, money, wedding rings and jewelry as some of the most commonly flushed items.

What is left of those materials is filtered through a septage and sludge screen called The Beast before it gets sent to a septage receiving station and placed into dumpsters for collection. The remaining waste is pumped further through the plant’s reclamation process.

Moab resident Dominic Bauer asked about how wastewater facilities keep up with — or don’t — the demands imposed on them by the increasing volume of waste, including that of pharmaceuticals.

“I’ve read about in cities, like Phoenix, where they have these large retirement populations and there are a lot of people that are not ingesting their pharmaceuticals and whatnot and they just go into the system,” Bauer said.

“Pharmaceuticals are a major environmental problem,” Mayers said.

“This system can’t take that, those molecules are so small, correct?” Bauer asked.

“It’s a biological process that takes those things up, but we’re not currently attuned to how to make the biological process pick up more of that stuff,” Mayers said.

“At the exit (flow) on the end of this plant, if you were to test the water, how much pharmaceuticals are in our water?” Bauer asked.

“It depends on plant volume,” Mayers said. “You’d be surprised how much varies among communities — huge variations. They’re at a very low concentration. You would say, that’s so low it’s almost not there, but when it gets into the environment species like frogs, that are very sensitive, they can start to show impacts of that material. At some point in the future, we’re going to have to figure out better ways we can do it… using reverse osmosis would remove that material, so it is possible.”

At the processing tanks where a mixing stage occurs, Mayers explained the importance of keeping the suspended biologically activated “scum” floating atop the liquid in balance.

Biological starter for the mixing process was obtained so that the plant didn’t have to wait to grow its own to help degradation process to start. Mayers said some of the biological starter came from a wastewater facility in Grand Junction, Colorado, and 50 gallons of starter — “all that it will ever need” — was purchased from another company.

“If you have a town that has a lot of hotels, like this one, and you’re doing a lot of laundry, and they’re using a lot of bleach — is there something that could offset this balance?” Bauer asked.

Officials designed Moab’s new wastewater facility with the town’s needs in mind, including the increase in lodging and residents in both Grand and San Juan counties. The plant has room to expand, if it needs to, in decades to come.

“It would have to be an awful lot of bleach, but you could kill a biological process,” Mayers said. “And then it will wash out and you won’t get any treatment or performance, but it’s unusual.”

The concentration and volume of bleach that it would take to “decimate” the plant’s processing tanks and reclamation “would be way beyond reach,” he said, and called it a minor concern.

“Resort towns have more of those kinds of problems because you have a much higher concentration of those things,” Mayers said. “You also get more grease and food waste from restaurants, and you get stronger wastewater in general because of restaurants and hotels, so a town like Moab has higher-strength wastewater than a similar town that wouldn’t have all the tourists coming in. We had to account for that.”

Once the reclamation process is completed, the water is non-potable, and what isn’t reused in the plant is released into the Colorado River. To disinfect the water before it reaches the river, the system utilizes 254 nanometers of UV light, the same that is used in various industries to disinfect food and medical equipment. The bulbs should last for 7,000 hours, Mayers said. A year is about 8,700 hours.

“They have been shown to last for much longer,” he said. “The disinfection process, on the end we have some utility pumps so water is used around the plant. We are reusing the water.”

Reusing water is one of the big differences between the old plant and the new plant, Mayers said. The old facility was using quite a bit of the city’s water, but now overall savings will be about $30,000 a year by reusing water.

In total, the new wastewater facility can process 1.75 million gallons of waste per day, versus about 1 million gallons per day with the old system, Mayers said.

“A million gallons per day is about 700 gallons a minute, in round numbers,” Mayers said. The new facility can handle a peak flow rate double that figure, he said, with room for expansion to handle triple the rate.

“We think, based on current projections, unless Moab grows at a much faster rate, [the facility has] a 50 year capacity,” Mayers said.

Looking at the new facility’s system, Moab City Council member Mike Duncan said, “This is awesome. We’re all looking forward to it. We just hope it stays in operation; for more than 20 years would be great, it depends on what the growth rate of the city and town are.”

The new Moab City Water Reclamation Facility has been in operation for about four months.

Ribbon-cutting ceremony and tours highlight state-of-the-art wastewater processing

“We think, based on current projections, unless Moab grows at a much faster rate, [the facility has] a 50 year capacity.”

Appreciate the coverage? Help keep local news alive.

Chip in to support the Moab Sun News.